summary

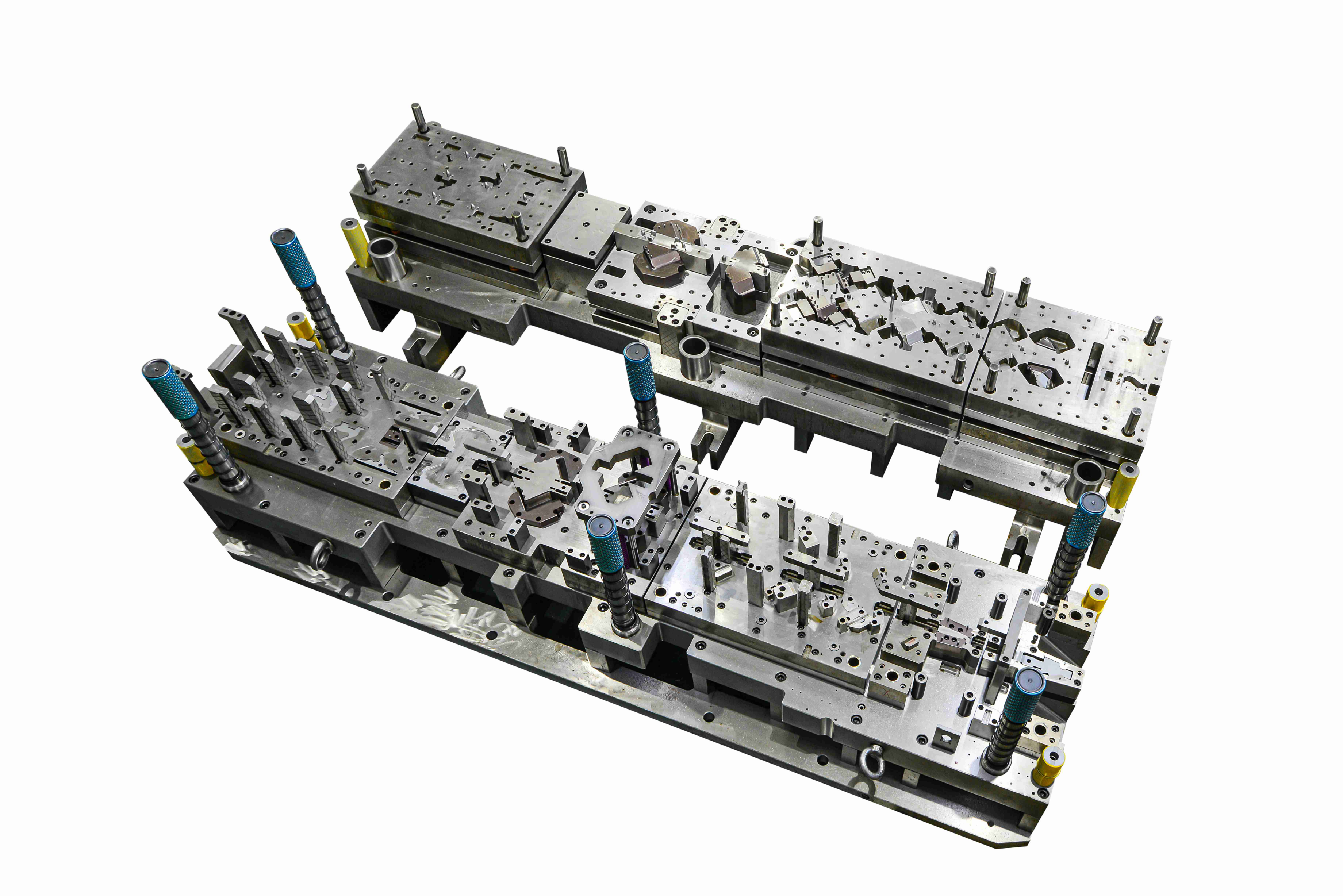

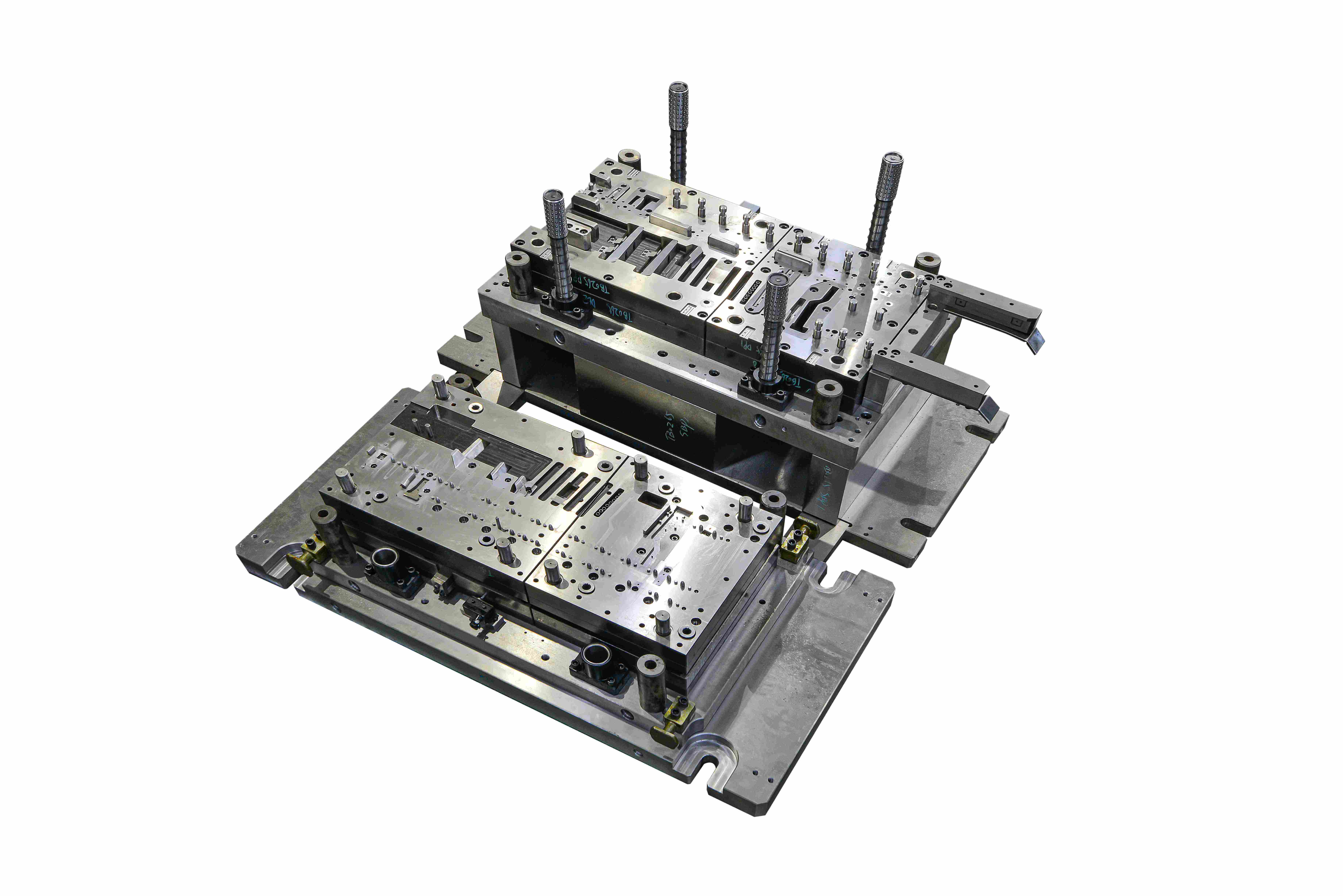

Since its establishment, standardization with the concept of "Mass Production of Molds" by perfect combination of all processes of mold making data.

It’s praised by customers for stable quality and on-time delivery, enhance our mold sales business has lasted over 18 years.

Features of APS Mold Manufacturing System

POINT1

The stability of quality and the fulfillment of on-time delivery of molds are favorable commenting by customers, enhance greatly increased the ratio of sales.

Quantity of molds produced in last 10 years (as of October 2021)UNIT:7363 sets

Items of mold produced : 2797 items

Number of molds produced: 4828 sets

POINT2

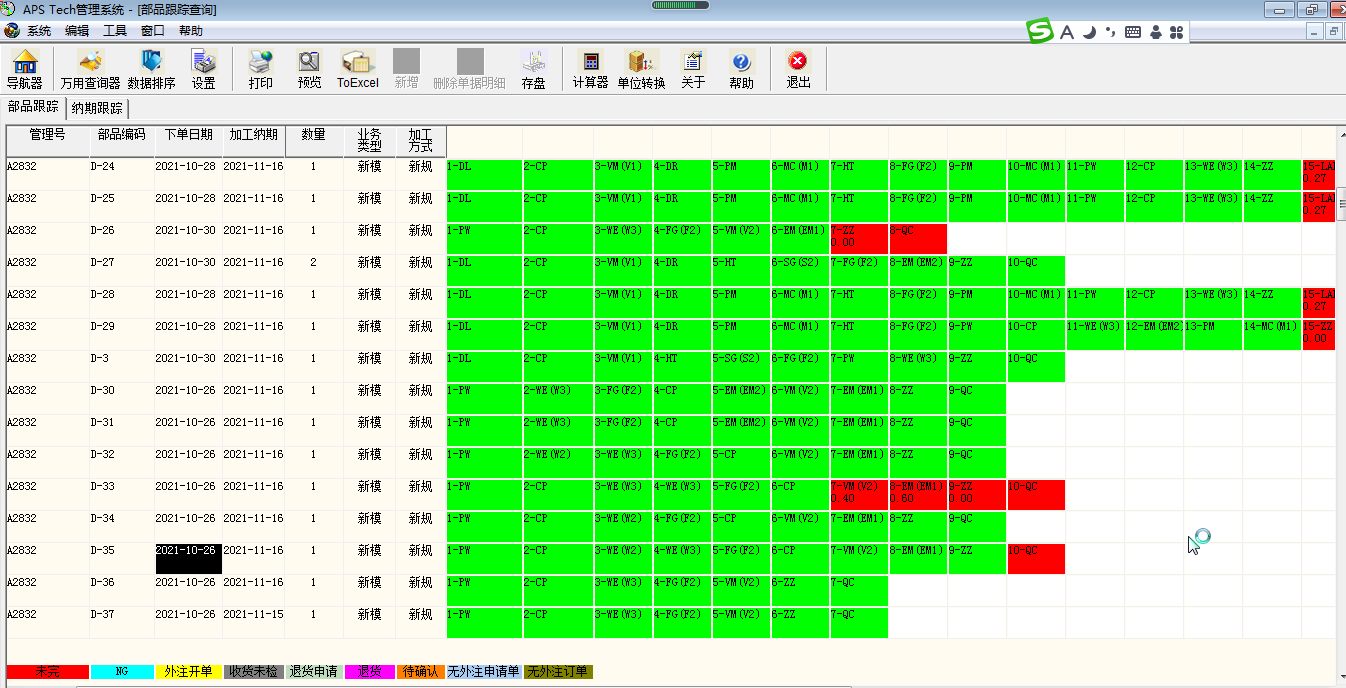

By utilizing our in-house developed ERP management System for mold production, setting monthly mass production processing schedule and target time, monitoring daily of the progress, enhance production achievement of delivery to customers over 98%.

POINT3

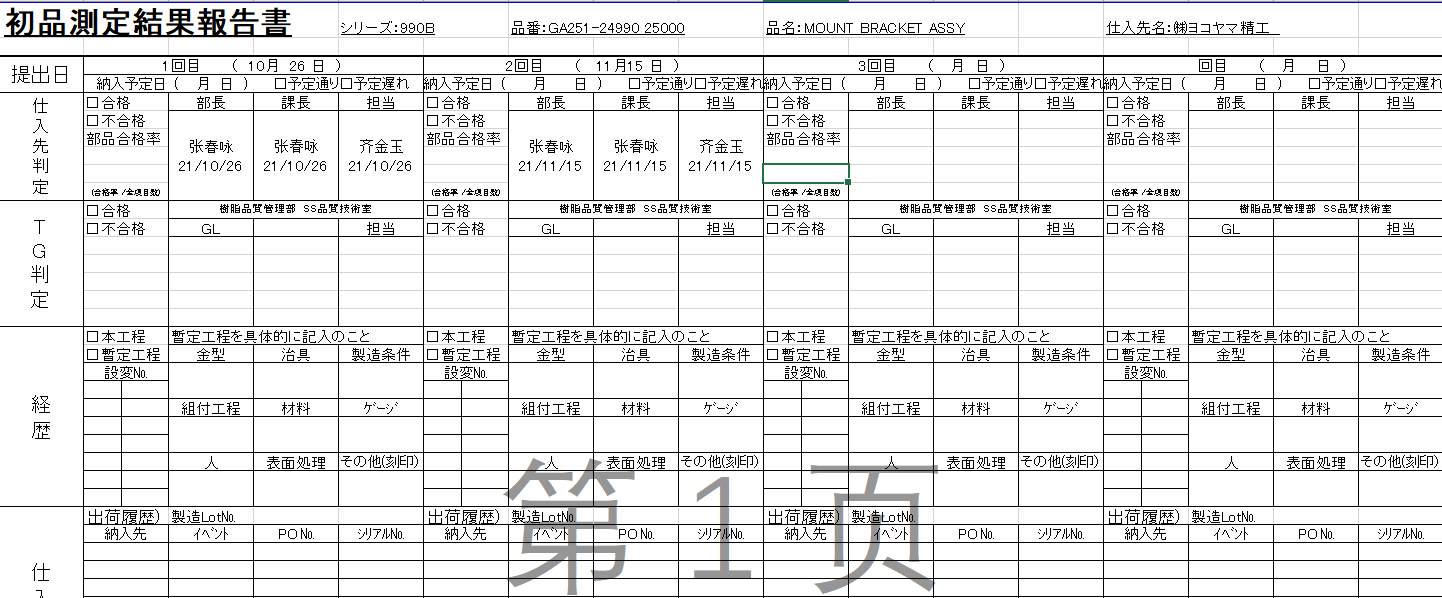

Special management performed on all the selling molds prior of delivery to prevent production failures occur after received by customers.After obtaining the customer's approval, disassemble all the mold parts to confirm whether there are any abnormalities such as gasket residues, then reconfirm and record under supervision of QA department according to check list before shipment, a video of the production status will be shooting record and sent to customer for reference.

The shipment of mold will only be arranged after get approval by customers. Because of this arrangement, some Press machines are specially operated independently only for trial production of molds.

By taking the above measures continuously, overseas customers do not require go to our factory for final confirmation of products, enhance APS is getting repeated orders from them.

POINT4

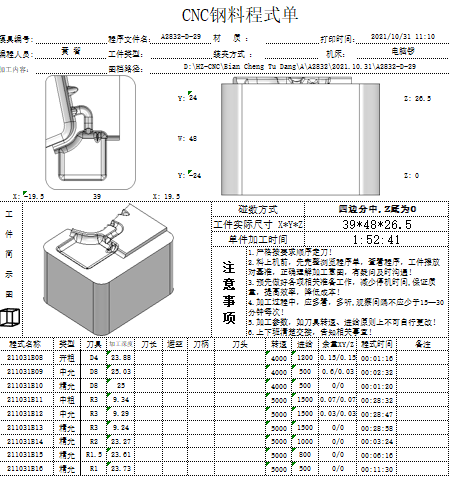

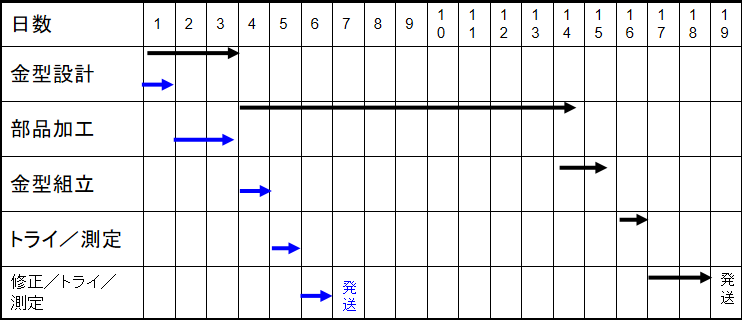

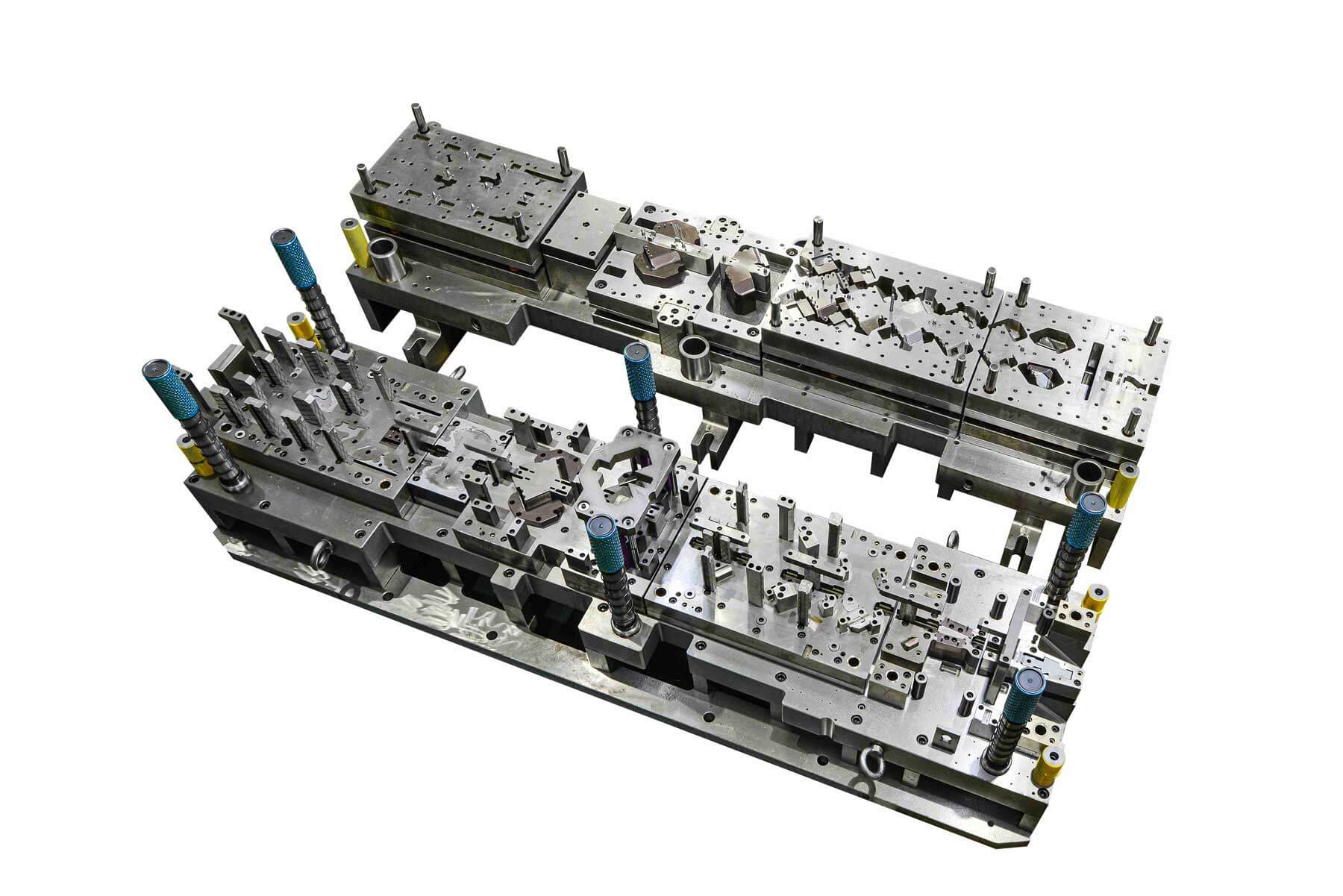

Although it is limited to specific shape of design, we are able to produce 60T progressive type mold in 7 days.Eliminate unnecessary discussion, designing and processes, prepare standard parts in advance by standardize of all countermeasures. Through the implementation of this overall standardization system, the normal lead time for mold production is reduced from 19 days to 7 days which has been greatly shortened.

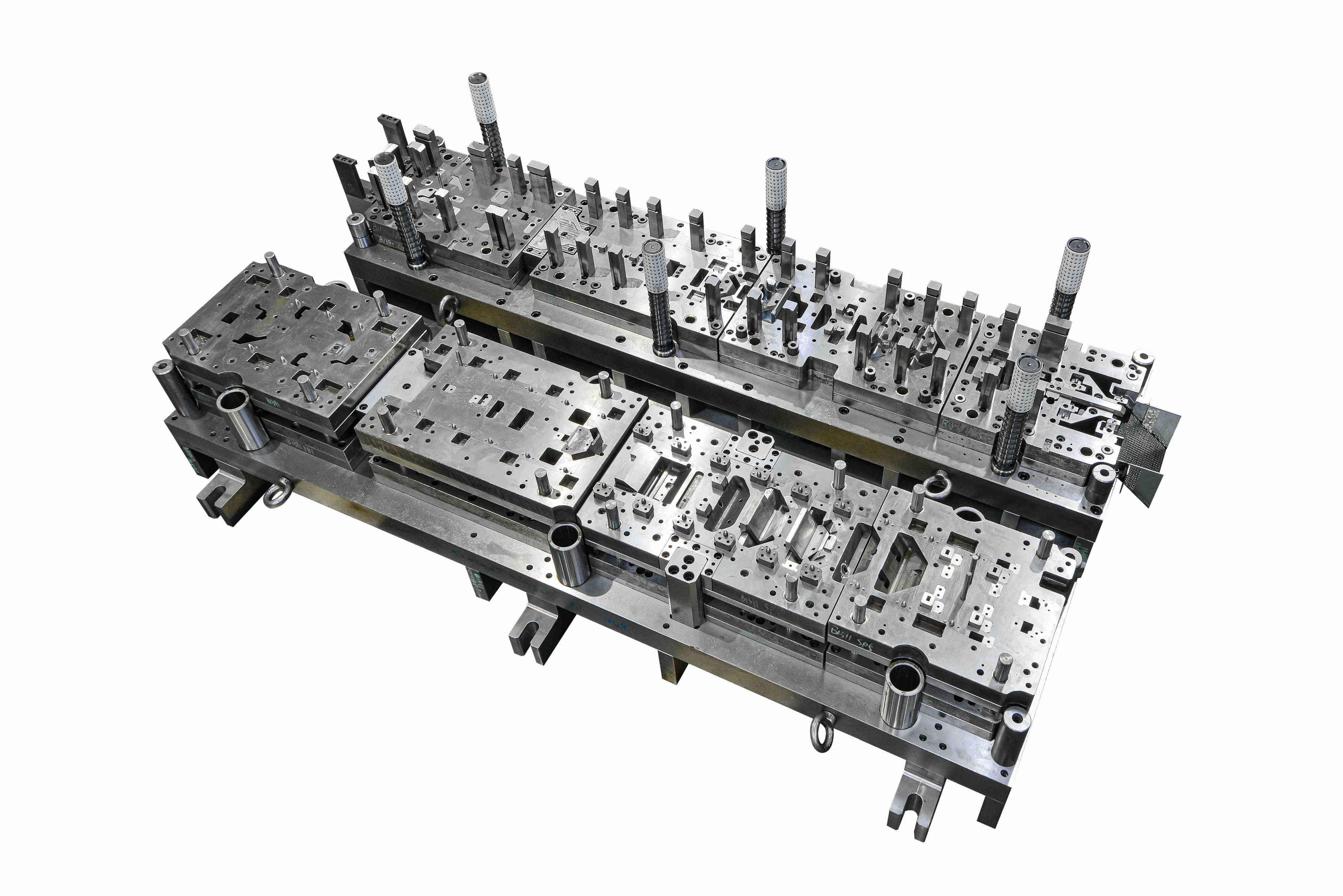

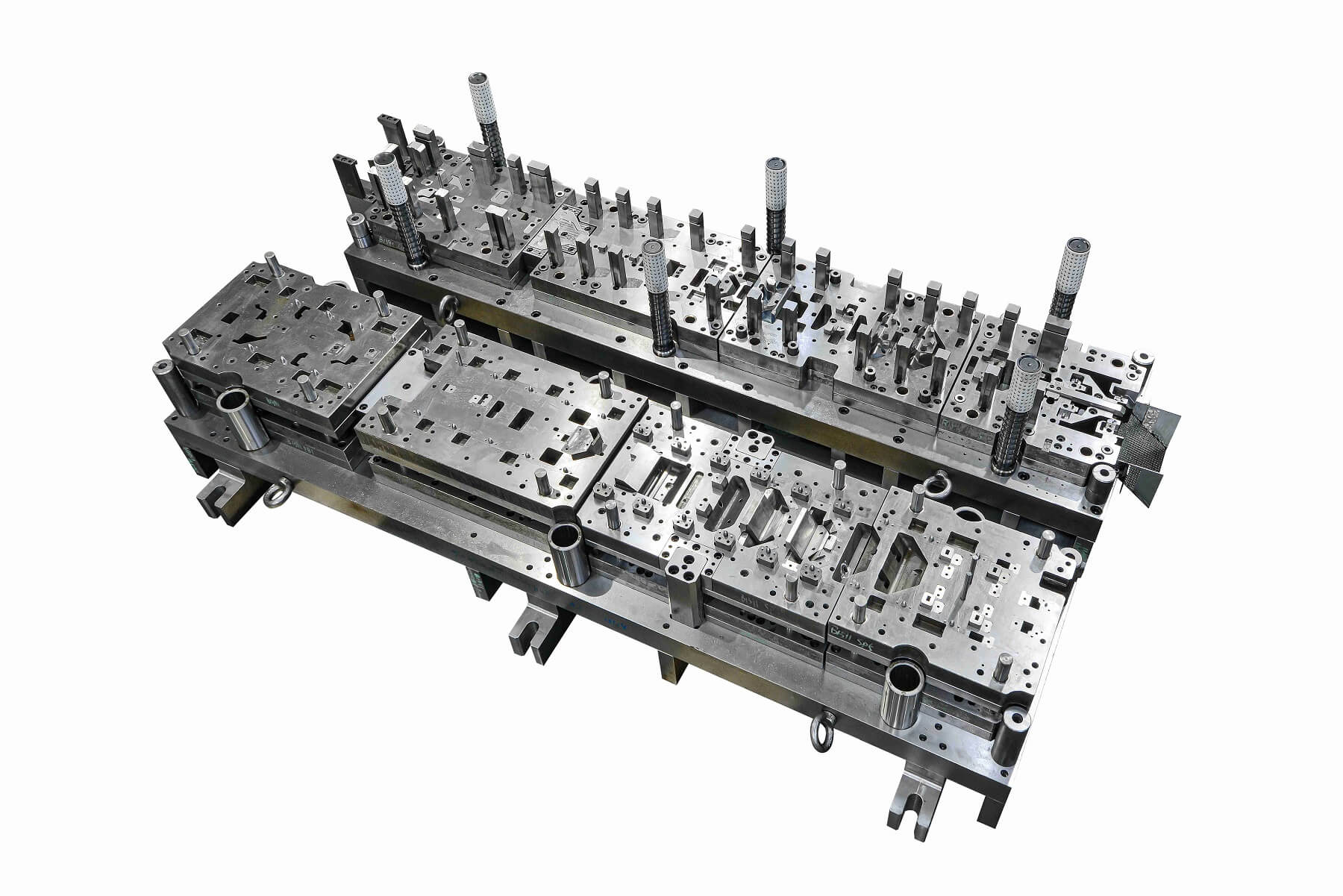

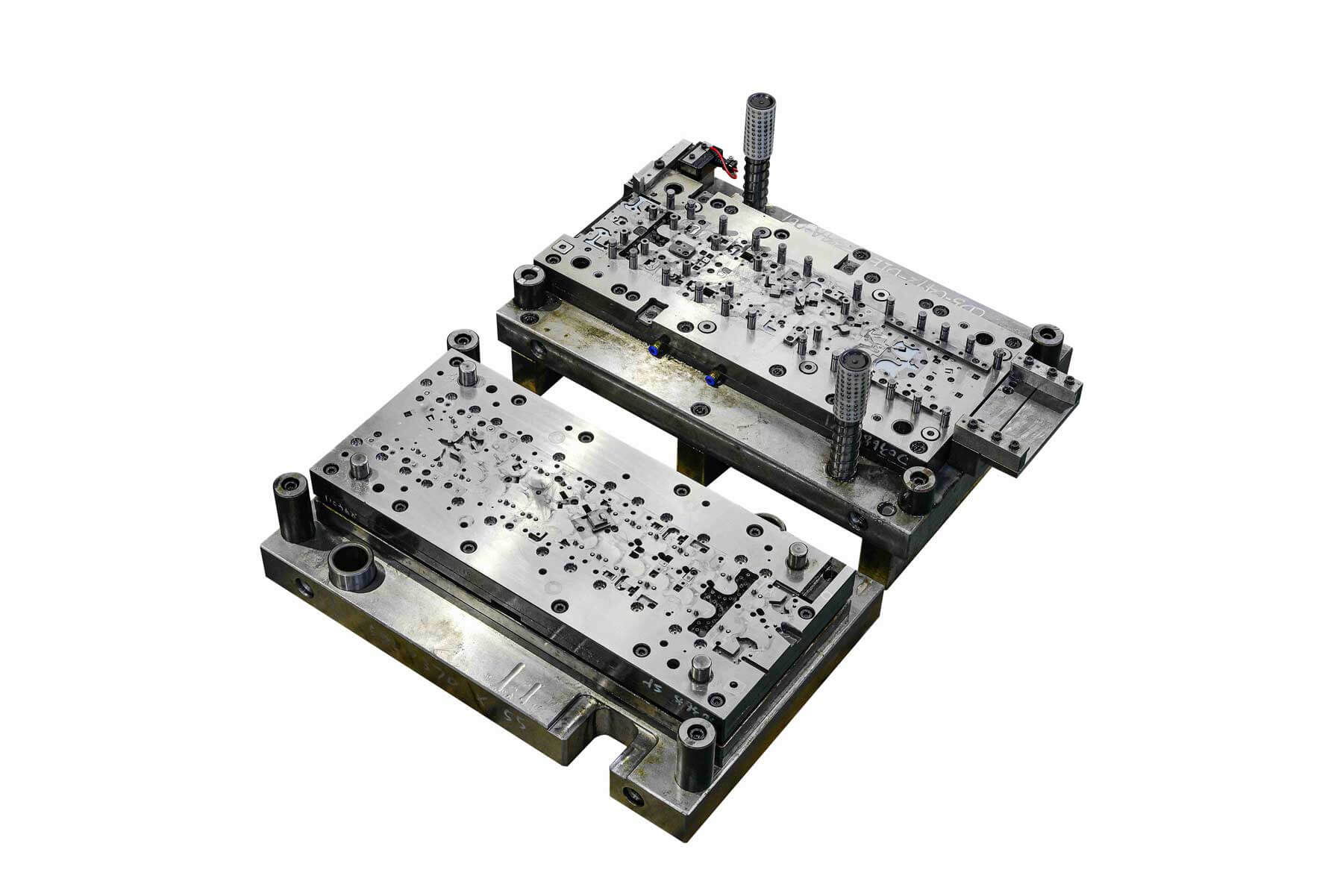

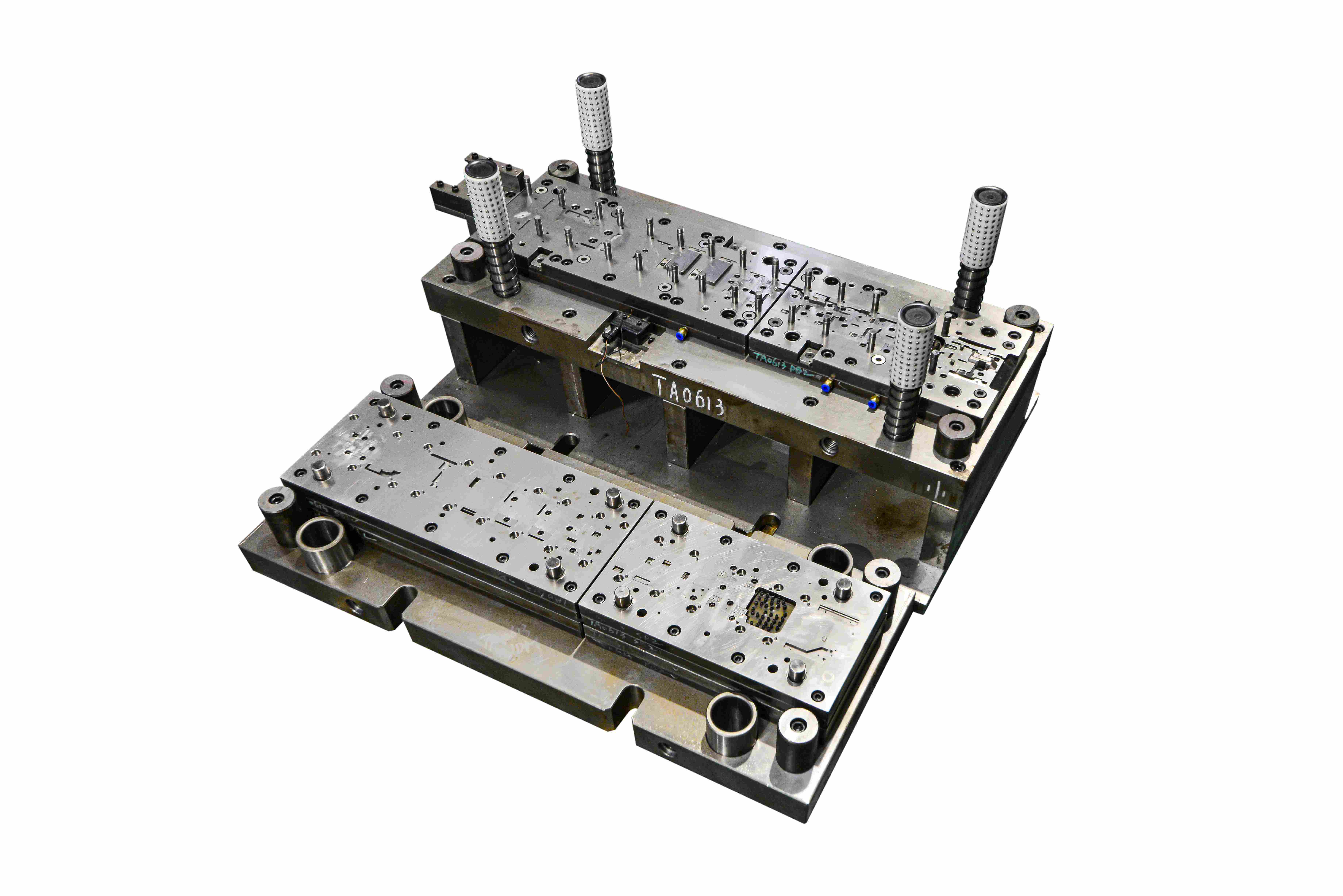

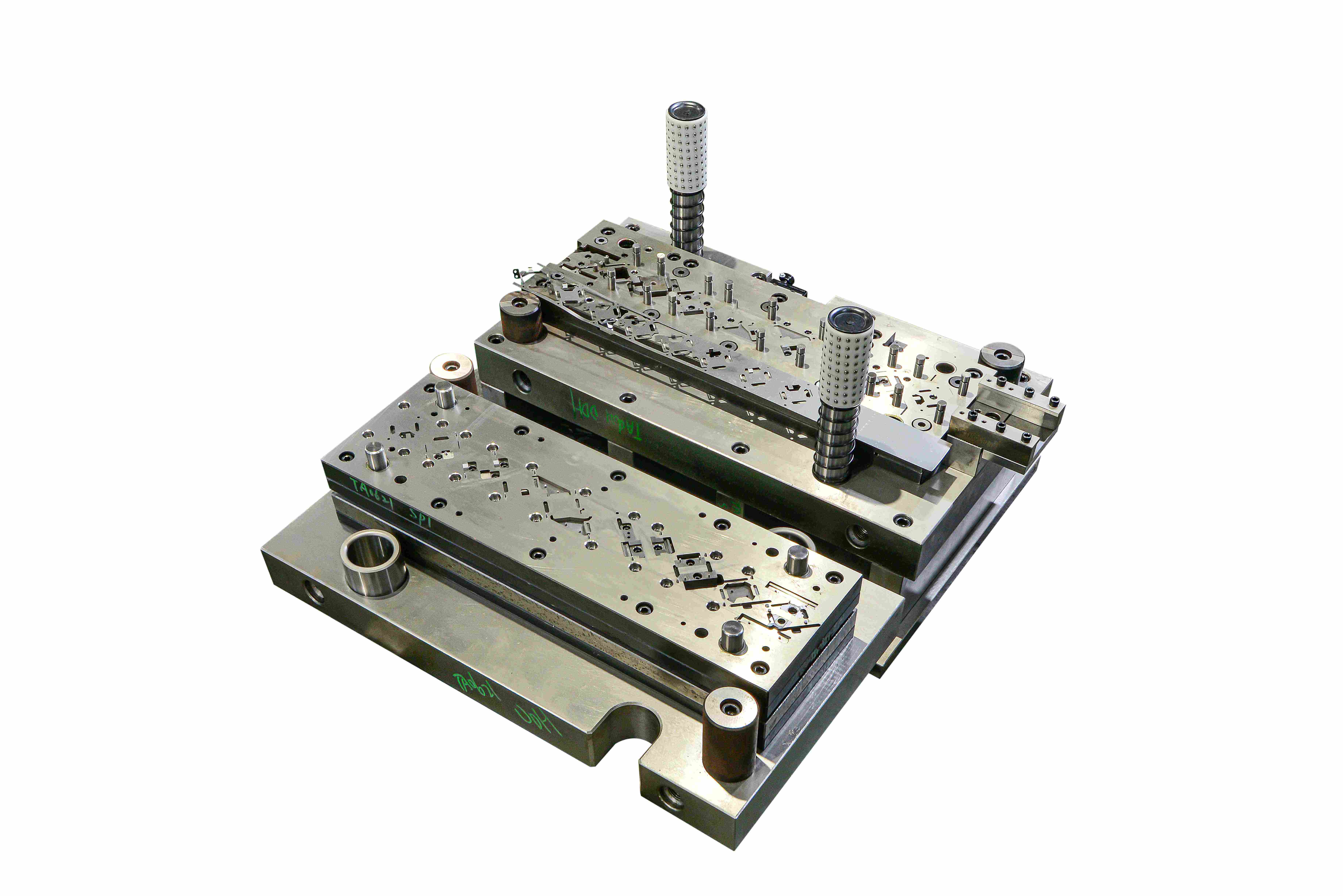

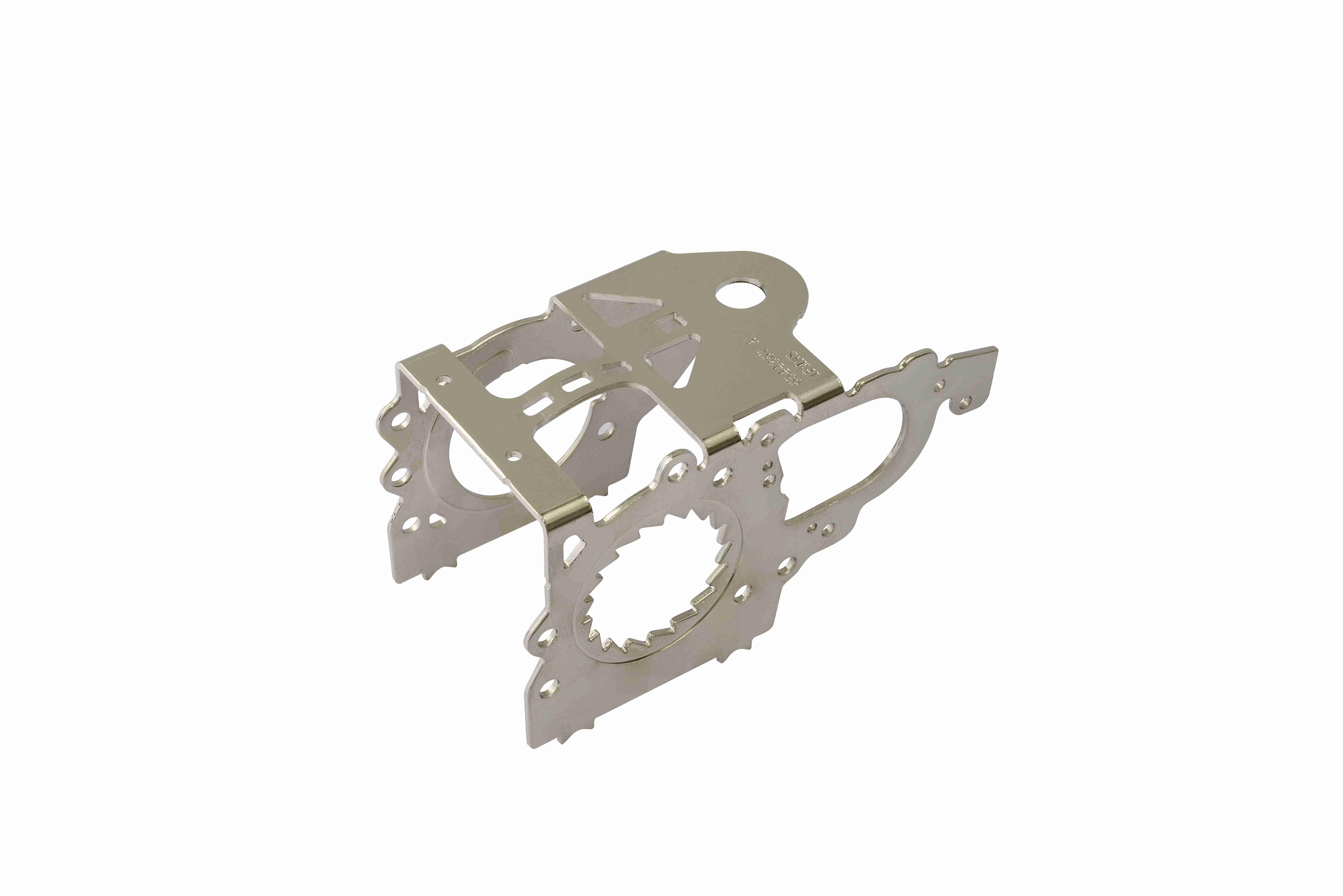

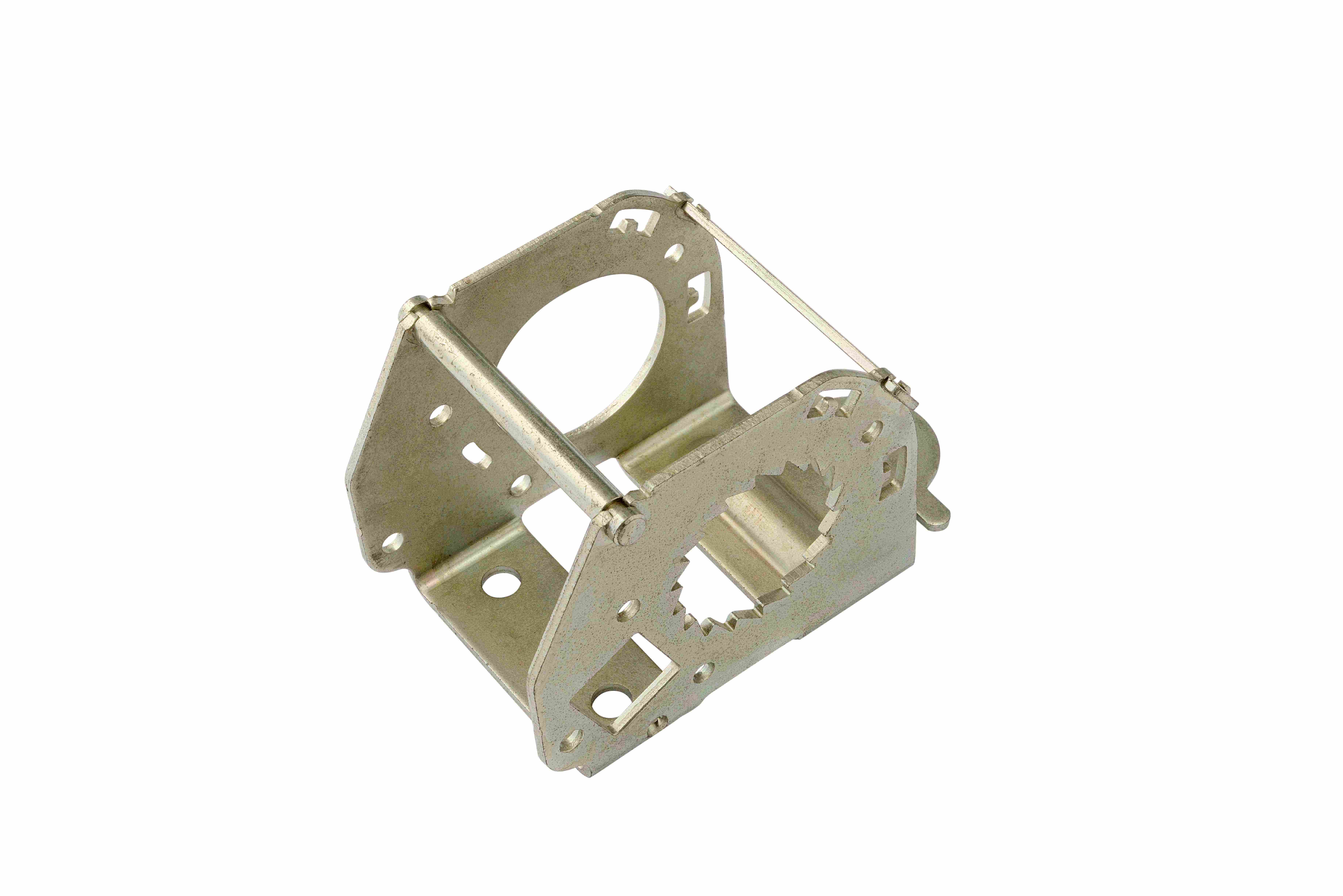

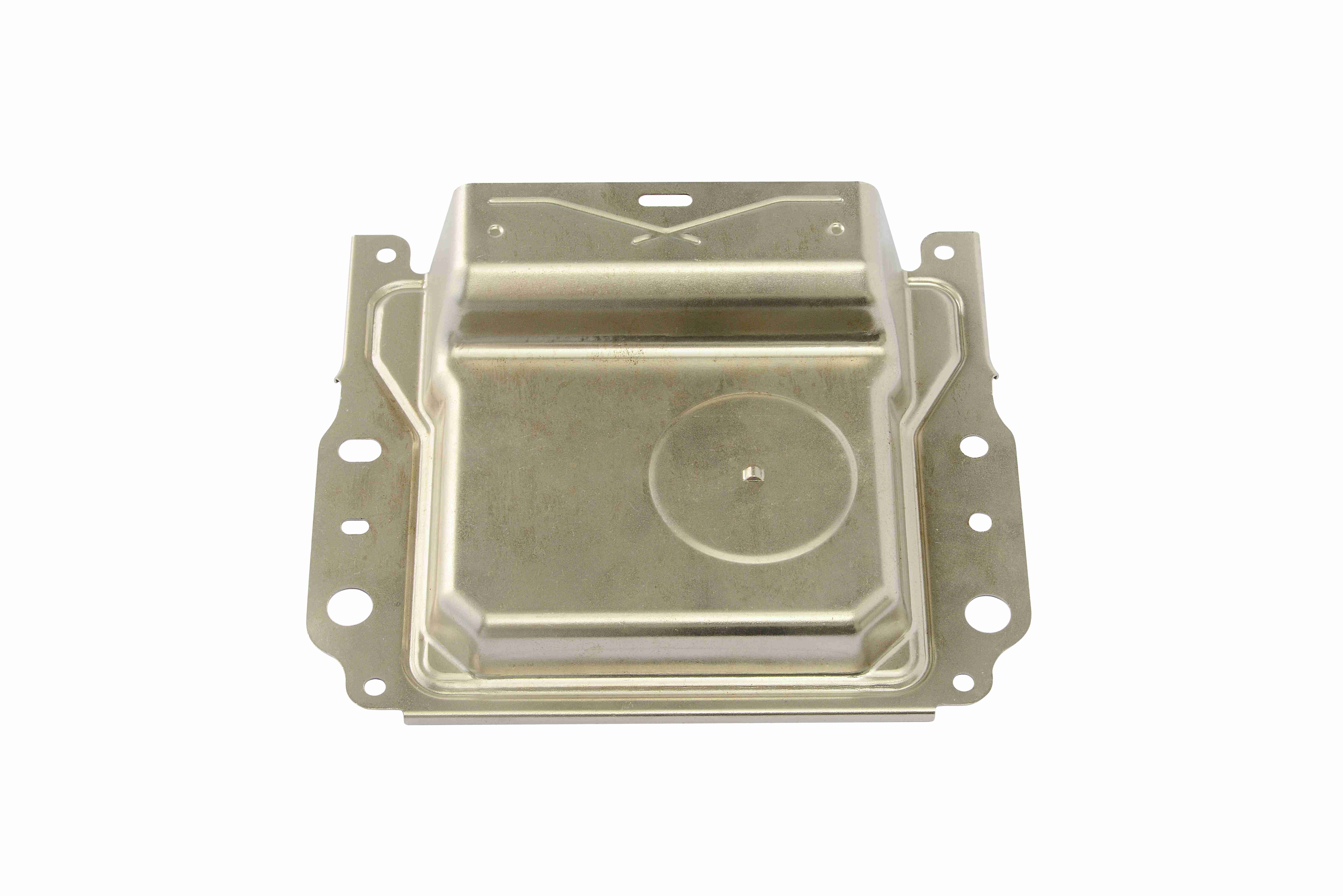

main products

Production performance

Production equipment

Production equipment

Large CNC machining center

Sodick wire cutting workshop

Sodick wire cutting equipment

Qinghong wire cutting machine workshop

Precision grinding workshop

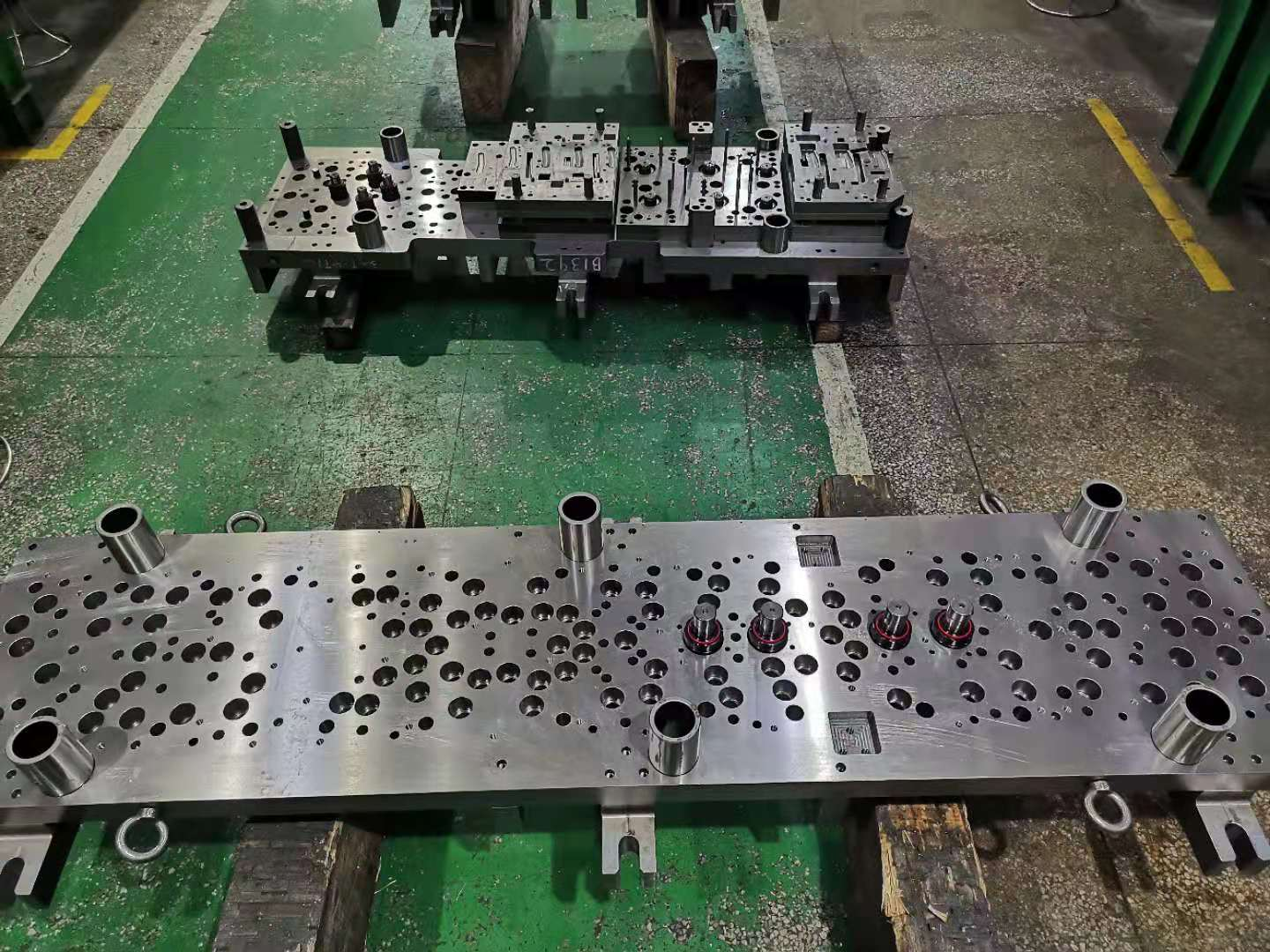

Mold assembly workshop

Electrical discharge processing equipment

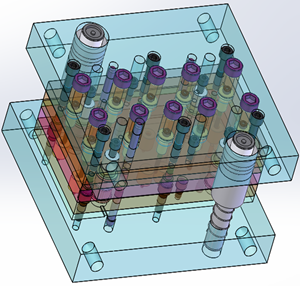

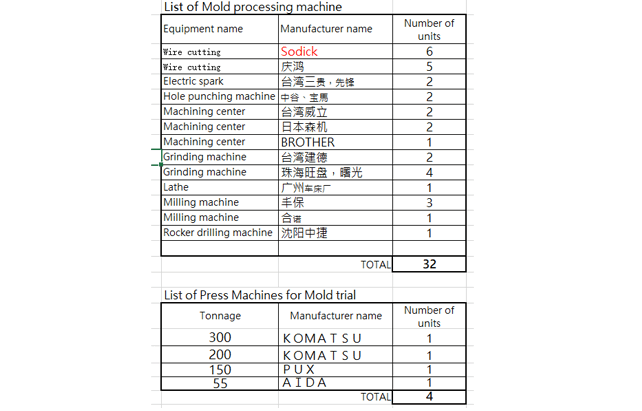

Mold processing equipment

Quality inspection

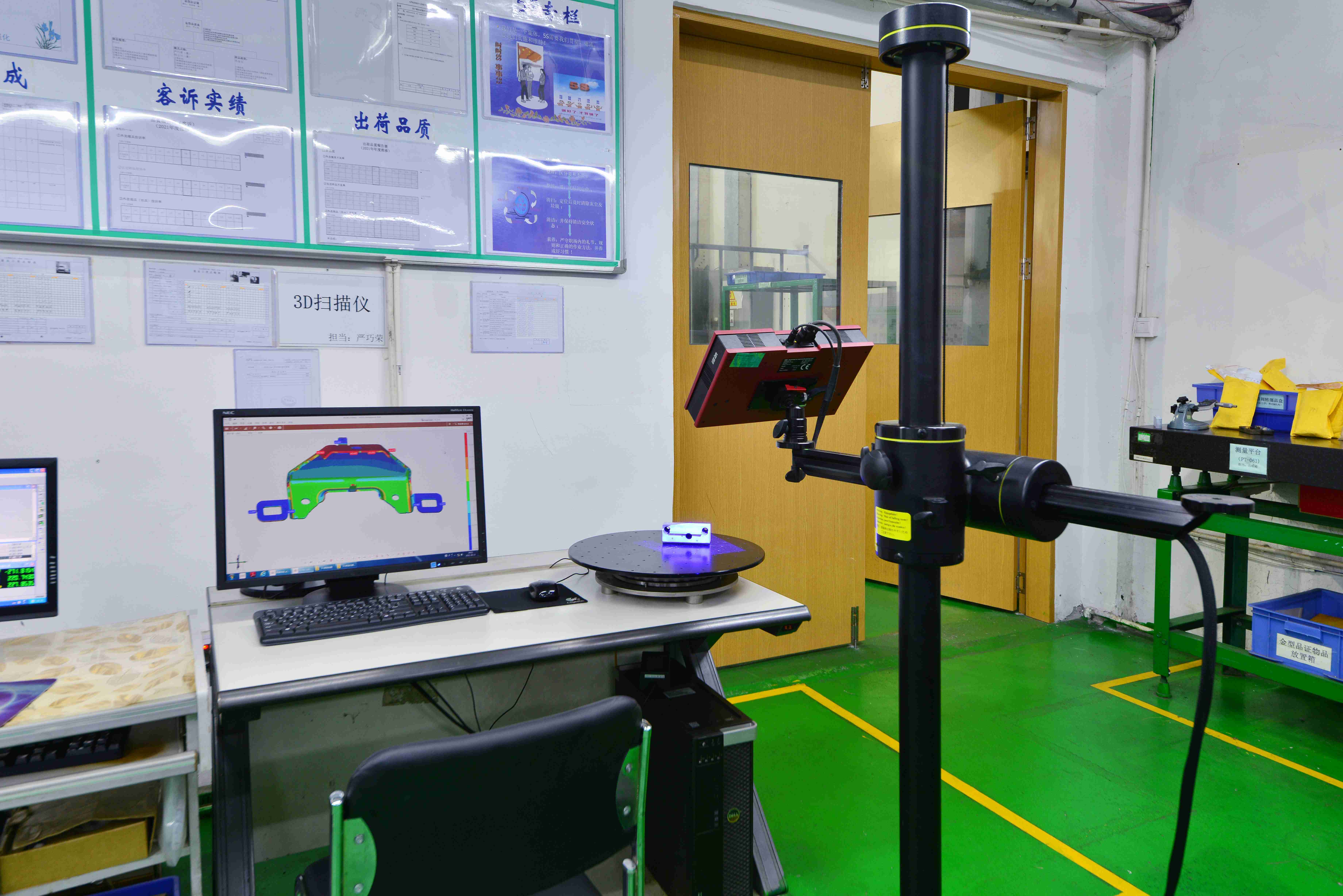

Quality Inspection & Assurance equipment

3D measuring equipment

3D Blue-ray Scanner